- Heat Pumped

- Posts

- Better Tools and More Data

Better Tools and More Data

A contractor's toolbag is their most valuable possession. Should we think past drills and wrenches?

This is part 4 in a series about accelerating heat pump adoption in America. If you missed the first, second, and third issues, check them out!

With contractors and consumers both climbing the learning curve, the next piece of the puzzle is giving them the tools and data to make smart decisions.

The Load Calc Problem

As discussed earlier, designing and installing heat pump systems can be technically complex. One of the most important steps that a contractor needs to take to right-size a heat pump system for a home is to complete a load calculation, which helps determine how much heating or cooling a home needs.

The Manual J load calculation method was designed to bring rigor and accuracy to HVAC sizing—but in practice, it’s often ignored, misused, or manipulated. Many contractors either skip it or fudge the numbers, leading to oversized systems and poor performance. Worse, inflated load calculations frequently steer homeowners toward gas systems or dual-fuel setups, undercutting electrification goals.

Manual J Barriers

Historically, contractors have relied on “rules of thumb”—like calculating BTUs based on square footage—to perform quick and simple load estimates. The alternative was far more time-consuming: taking detailed measurements of every room, assessing insulation levels, and manually inputting data into spreadsheets or even paper-based calculators. For most contractors, especially when swapping out a gas furnace was the norm, that level of effort simply wasn’t worth it.

But heat pump systems are different. These old shortcuts often lead to oversized equipment that performs poorly or even fails. Fortunately, there are several alternative approaches that can lead to more accurate load calcs without a huge amount of effort.

Software To The Rescue

Software tools from companies like Amply Energy and Conduit use real-time LiDAR scanning and AI to generate accurate 3D models of a home, saving contractors hours of manual data collection. Augmented reality features allow quick visual design mock-ups, helping homeowners understand system layout like mini-split head locations or duct placement.

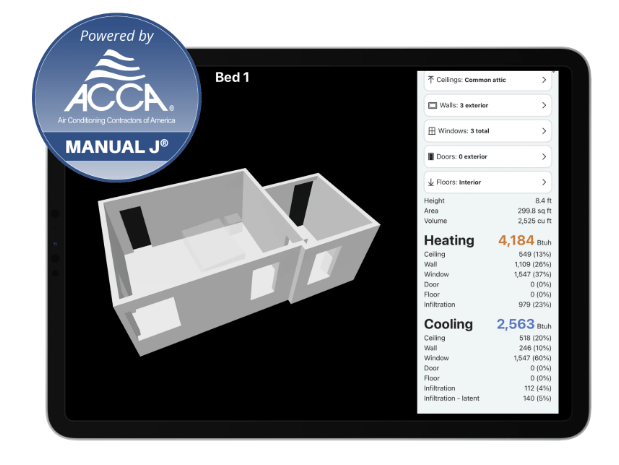

Critically, the software produces ACCA-certified Manual J reports, giving contractors precise heating and cooling load calculations while satisfying permitting and rebate requirements. Additional capabilities include auto-importing publicly available property data, setting climate-specific design conditions, customizing the building envelope, and producing clear design documents for both homeowners and installation teams.

Amply’s iPad app gives contractors an efficient method to achieve accurate, ACCA-certified Manual J load calculations (Source)

These tools not only help contractors speed up their load calculation considerably, but also create an opening to have a more in-depth discussion with the homeowner.

If someone was doing it the right way before—where they were going in, taking out a laser tape measure, hand-drawing a 2D floor plan with all the dimensions, and then later going back to enter all of that into WrightSoft to do a really good load calculation—that’s a four-hour exercise. We take about 15 minutes. So we’re much, much, much faster than the old right way. And we’re radically better in terms of accuracy.

What a bunch of our customers find is the homeowner follows them around because the scan is kind of captivating—like, 'What are you doing?' It becomes a great conversation piece. So really, the 15 minutes are just interwoven with this great opportunity to get to know the customer, get to know their priorities, and build the right system the right way

Contractors who leverage these tools can produce more accurate load calculations, save significant time, and shift the sales conversation toward outcomes and long-term value—rather than just price. But there’s a catch: without a solid understanding of Manual J fundamentals, even the best software can lead to flawed results. As the saying goes, “garbage in, garbage out.”

It’s worth noting that the Manual J methodology is currently under review by ACCA, with an emphasis on the “survey” component of the process—the data that contractors need to collect in the field. The hope for the industry is that the updates will reduce inconsistencies and create a more reliable, streamlined process that delivers more accurate results and clearer guidance for contractors.

Performance-Based Heat Loads

There’s another way to achieve a load calculation that has nothing to do with energy models like Manual J, and some professionals believe it’s an essential step in the process.

Models give the illusion of accuracy, but there is no way to know if the output is accurate without comparing the results to real-world performance.

A performance-based heat load uses real-world data from the existing heating system in the home to accurately and reliably size the equipment for the new system. As outlined in Drew Tozer’s book Feel Good Homes, there are two methods of using performance data:

Method 1: Energy Consumption

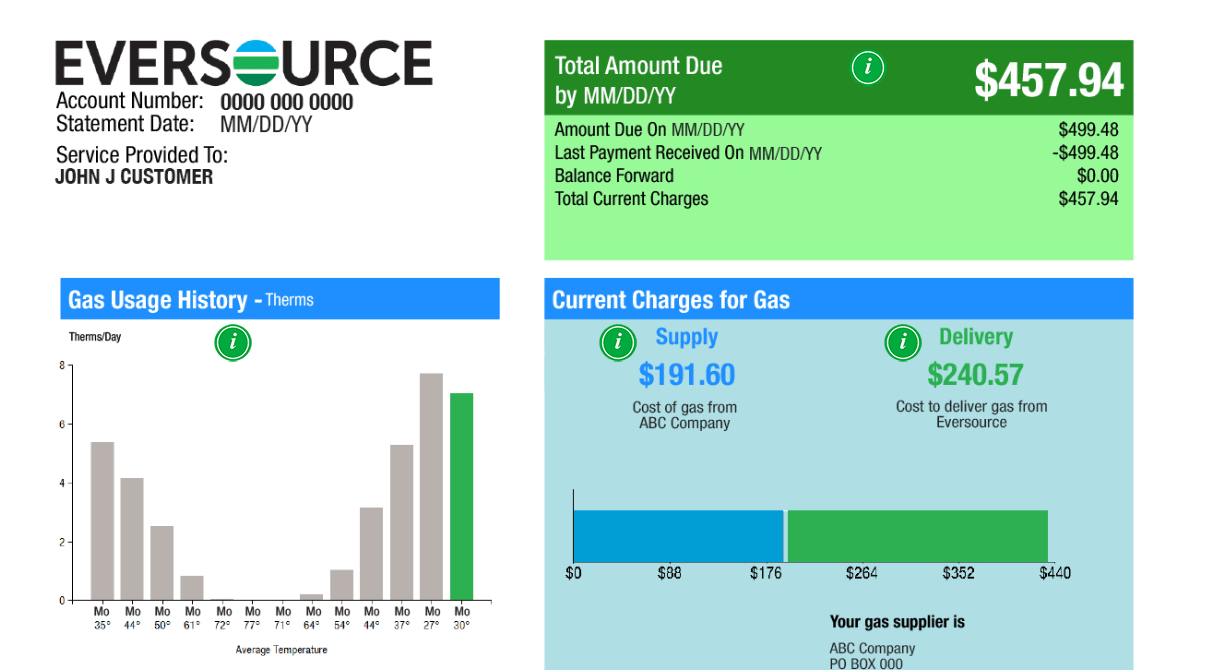

This method looks at a home's actual energy consumption—typically from heating fuel or electric bills—paired with local weather data to estimate how much heat the home truly needs. By converting fuel usage into BTUs and analyzing it relative to outdoor temperatures, contractors can calculate a more accurate heating load based on real-world conditions rather than theoretical models. This method relies on consistent historical data and can underestimate needs if the home was underheated or supplemented with other heat sources.

Method 2: Runtime Data

This refers to how long an existing furnace operates over a period of time. This data can be used to estimate a home’s actual heat load by tracking how often and how long the furnace runs at the design temperature (typically the coldest days of the year). By analyzing this data—especially during the coldest periods—contractors can infer how much heat the system is delivering to maintain indoor temperatures. If the furnace short-cycles frequently during extreme cold—for instance, running for only 30 minutes over the course of an hour—that indicates that the system is oversized (by two times, in this example). A right-sized system would run at close 100% capacity at the design temperature.

Gas bills can be used to determine a home’s actual energy consumption, which can then be paired with local weather data to estimate a heating load (Source)

Energy consumption is typically easier to get than runtime data because almost every homeowner can scare up some old gas bills, whereas some homes don’t have equipment (either the furnace or the thermostat) that provides accurate data. Needless to say, both of these methods only work for retrofits where an existing system is being replaced.

Performance-based data can be used to verify a Manual J load calculation by serving as a real-world cross-check against the modeled heating load. If the energy use or runtime data shows significantly lower heating demand than the Manual J suggests, it may indicate the calculation was overly conservative.

One company that is operationalizing performanced-based heat loads is Thermentor. Their software product analyzes a home’s actual energy consumption and local weather data to estimate heating and cooling loads. It interprets utility bills and combines them with temperature data to produce actionable design metrics and even estimates future bill impacts.

Additionally, Thermentor flags available rebates and incentives based on the proposed system, helping contractors present everything clearly to homeowners. By comparing actual performance to predicted loads, contractors can catch oversizing errors, justify smaller, more efficient equipment, and design systems that better match the home’s true needs.

Equipment Ratings ≠ Real-World Performance

Once a contractor has an accurate load calculation, the next step is to choose the right heat pump to match that load. In order to maximize the homeowner’s savings on electricity bills, he needs to choose a heat pump that is right-sized in terms of capacity (BTUs) but also efficiency.

SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Seasonal Performance Factor) are two standard metrics developed by AHRI (Air-Conditioning, Heating and Refrigeration Institute) used to measure the efficiency of HVAC systems. The ratings are determined by lab testing done by the manufacturers, and certain equipment must meet minimum efficiency standards as required by DOE.

The problem is that the efficiency ratings often don’t reflect how heat pumps actually perform in real homes. The lab tests are done under controlled conditions and the results are plugged into a computer model that estimates seasonal performance. But that model is based on climate assumptions and test points that don’t line up with how most systems run day to day.

All of these tests are conducted at fixed compressor speeds and fixed fan speeds... it’s a test mode and has little to do with how the system actually operates in real life.

The discrepancy between lab-testing data and real-world performance is more than academic, and it affects more than just efficiency. Chasing ultra-high SEER ratings (higher = more efficient) can sometimes come at the cost of comfort. Some equipment achieves impressive SEER numbers at the expense of humidity control – but unless a contractor has tested that equipment themselves, they would have no way of knowing this:

We don’t require manufacturers to publish latent performance [humidity]… and we’re allowed to slap these things in. There are multiple mini-split manufacturers who have absolutely no performance data for latent capacity… How do I know which one to pick? You don’t.

This can lead to a range of negative outcomes, from mild discomfort—like a home that feels cool but clammy—to more serious issues, such as hidden moisture buildup and mold growth. The tradeoff between efficiency and performance isn’t obvious to the homeowner—or even to many contractors—unless more granular performance data is available.

One potential solution comes in the form of load-based testing. Unlike conventional lab tests that fix indoor and outdoor conditions to evaluate performance under idealized settings, load-based testing simulates real-world dynamics. One testing methodology, developed in collaboration by a series of international working groups led by the Canadian Standards Association (CSA), applies a virtual building load to the system in a controlled laboratory environment, letting the equipment respond using its built-in algorithms—just as it would in a real home.

With a load-based test, you're measuring the heating or cooling capacity of the equipment in real time as it's running. And you're basically saying, I'm going to create a simple model of a building in the lab, that has energy coming in or out through the enclosure, and you're letting the equipment try to match that energy (with the opposite sign) by providing cooling or heating.

Instead of testing fixed speeds and conditions, the load-based method continuously adjusts the heating or cooling demand depending on outdoor temperatures. This simulation allows for more complete and accurate data about how a heat pump will perform across a realistic range of scenarios.

The result is performance data that’s far more representative of what a homeowner will experience, helping contractors make better design decisions and reducing the risk of oversizing or misapplication.

Quilt: The Smart(est) Heat Pump

If real-world performance data and smarter system design are the future of home heating and cooling, there’s one company that’s already building that future into every unit they ship.

Founded in 2022, Quilt is a vertically integrated OEM building ductless heat pump systems with software, connectivity, and user experience baked into every layer of the product.

Rather than relying on third-party thermostats or outdated controls, Quilt’s system is designed as a complete stack: hardware, software, and user interface all working together. This allows their equipment to operate as a true smart system—able to sense, adjust, and optimize in real time.

Unlike traditional thermostats, which have no insight into what's happening inside the unit, Quilt’s system knows exactly what speed the compressor is running, the temperature of the coils, and how fast the fans are spinning. With this data, it can intelligently modulate performance to balance efficiency and comfort based on conditions in the home.

A Nest or Ecobee [thermostat] doesn’t know what speed the compressor is, it doesn’t know the temperature of the coils in the outdoor unit, and it fundamentally can’t…. Because we’ve integrated it, we can build algorithms that work across all those data points and optimize specifically for the hardware we’ve created.

At the core of this system is an unusually powerful onboard computer—reportedly over 1,000 times more capable than the chips in typical mini-splits—enabling sophisticated algorithms to run continuously.

The result is not just higher efficiency, but better lived experience: consistent temperatures, faster response times, and reduced energy waste. This is especially impactful in homes with varying thermal loads, where traditional systems struggle to maintain even comfort.

In short, it’s the Cadillac (or Tesla) of heat pumps.

Smart Thermostats

Quilt may be the gold-standard for a completely optimized, data-based system, but there is still plenty of room for improvements in all kinds of heat pump systems using a real-world, performance-based data approach.

Smart thermostats can serve as a valuable bridge by collecting runtime data, tracking temperature trends, and detecting patterns that reveal performance issues or inefficiencies. Paired with cloud connectivity and analytics, they can provide both homeowners, contractors, and even utilities with powerful insights:

I’ve been very vocal about begging power companies… to just buy a butt-ton of thermostats that contain data loggers. And instead of the incentive program being “We’ll give you free stuff if you let us shut off your air conditioner on the hottest day of the year”... instead, trade it for the data. Data trumps everything. Field data—like actual house field data—not this computer model BS. Like, we lived in this house, we had data loggers, this is what happened.

While they may not have full visibility into equipment internals like Quilt’s system, smart thermostats can still enable basic diagnostics, trigger alerts, and help fine-tune control strategies while creating a trove of performance data—all steps toward a more responsive, efficient home heating experience.

Pairing a heat pump with a smart thermostat optimizes performance and creates data sets that provide valuable feedback to homeowners and system designers (Source)

What’s more, with enough anonymized data points, we could refine our understanding of what causes heat pump failures or inefficiencies.

For example, by analyzing hundreds or thousands of installations, algorithms might detect that homes of a certain style in Climate Zone 5 consistently struggle to maintain setpoint when winds are high, which could lead to better sizing recommendations or envelope fixes.

In short, feedback loops from field data will help continuously improve both technology and installation practices.

There is one significant caveat: there is evidence that suggests that third-party smart thermostats should only be used with non-variable speed heat pumps. When used with variable-speed units, third-party thermostats generally don’t support proper operation in variable-speed mode, and it has been shown that their use results in on/off cycling behavior that greatly reduces efficiency.

One solution? Smart thermostats provided by the OEM and natively integrated with the unit, as such products become available.

Solutions Summary

Designing better heat pump systems requires moving beyond outdated rules and unreliable sizing. New tools—from advanced software to performance-based methods and smart controls—offer faster, more accurate, and data-driven ways to match equipment to real-world home needs. Better tools and data are force multipliers for the trained workforce and educated consumers we discussed earlier.

Solution | What It Looks Like in Practice |

Next-Gen Load Calc Software | Tools like Amply and Conduit automate Manual J load calculations using 3D scanning and AI. These platforms slash analysis time from hours to minutes while improving accuracy and enabling transparent, data-driven conversations with homeowners. |

Performance-Based Load Calculations | Energy consumption and runtime data from existing systems can be used to calculate actual heating loads. This grounds system design in lived experience rather than theoretical models. |

Manual J Reform | ACCA is revising the Manual J standard to improve accuracy and consistency. Emphasis on the survey process aims to reduce human error and create more reliable, usable outputs for contractors in the field. |

Load-Based Equipment Testing | Experts like Bruce Harley advocate for lab testing that simulates real-world building loads instead of fixed-speed lab conditions. This yields more accurate performance predictions, helping contractors choose equipment that performs well in the field. The newest version of the industry test procedure includes some elements of load-based testing. |

Fully Integrated Smart Systems | Companies like Quilt combine hardware, software, and user interface to create smart heat pumps that self-optimize using real-time data. These systems deliver precise control, fast response times, and consistently high comfort. |

Smart Thermostat Integration | Smart thermostats collect runtime data and provide ongoing performance feedback. When paired with analytics platforms, they enable diagnostics, fine-tuning, and insights for installers, utilities, and homeowners alike. |

Data-Driven Field Feedback | As Alex Meaney suggests, widespread use of data-logging thermostats could generate powerful insights into system performance, driving continuous improvement in design practices and identifying systemic installation flaws across climate zones. |

This is part 4 in a series about accelerating heat pump adoption in America. If you missed the first, second, and third issues, check them out. Thank you to Climate Drift for letting us share this piece with the Heat Pumped community!